Selected cases

Västra Strandens ARV

Laholmbugtens VA

Reduction of sewage sludge and increasing gas production

Wastewater sludge is an unavoidable residual product of waste water treatment, therefor supplies are constantly working on optimizing processes around minimizing the amount of sludge that must be disposed of.

At most larger sewage treatment plants, the amount of sludge is reduced by anaerobic digestion, and this is also the case at Västre Stranden’s WWTP in Halmstad.

When digesting the sewage sludge, part of the sludge’s dry matter is converted into biogas (methane gas CH4), which is an excellent fuel for gas engine-/boiler systems. Laholmsbuktens VA has used biogas as an energy source for several years and will continue to do so for many years to come.

Gas production has been increasing in recent years and a continued increase is expected in the future, so that gas production in 15 years will have increased by 25% compared to today.

Laholmsbuktens VA therefore in 2020 decided to replacement the existing gas engine with a new gas engine, in order to future-proof in relation to future gas production.

Västra Strandens ARV

Laholmbugtens VA

NPM 530

530 kW Electricity

544 kW Heating

2021

<7 years

Wastewater sludge is an unavoidable residual product of waste water treatment, therefor supplies are constantly working on optimizing processes around minimizing the amount of sludge that must be disposed of.

Why a NISSEN Power Modul 530?

The tender’s requirement was stepless turnover of 120 to 200 m3 of biogas per hour with an energy content of 5 to 6.5 kW/Nm³. The emission requirement from the gas engine was 150 mg NOx/MJ fuel.

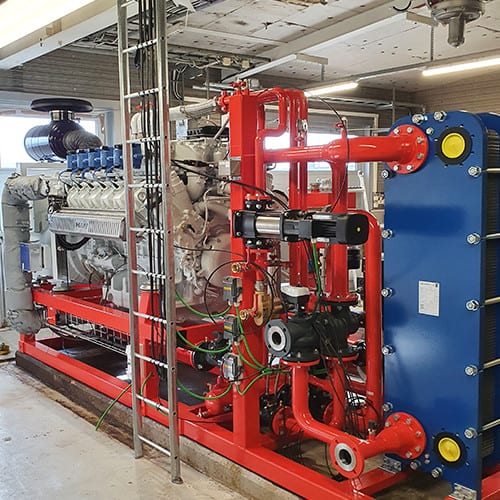

Based on these specifications, NISSEN energy chose to offer our NISSEN Power Module 530 of 530 kW in order to be able to operate with as high an efficiency as possible, and at the same time have room to increase gas production in the future.

NISSEN energy a/s was chosen as general contractor for the task based on the criterion of the most economically advantageous offer assessed on the basis of construction price, costs for operation and maintenance (Total Cost of Ownership (TOC)), quality and references to previous deliveries of the same nature.

The task consisted of dismantling the existing engine, preparing the existing engine compartment for the installation of a new engine, delivery of a new control and power board, connection to gas, conversion of the heating system, exhaust system and ventilation system.

The gas engine system and control and power board were built at the NISSEN workshop in Skanderborg and subsequently installed at the WWTP. The plant was commissioned and handed over to Laholmsbuktens VA in May 2021 and by the end of January 2022 had run 6,500 operating hours.

The customer experience

Laholmsbuktens VA AB took the decision in 2020 to replace the existing gas engine at Västra Strandens Reningsverk with a new gas engine.

After a normal bidding round, NISSEN energy was chosen as the supplier of the new gas engine, type MAN E3262 LE212.

The delivery was started in the spring of 2021 and completed during the summer.

Purchase and subsequent assembly/start-up were carried out without any problems and we have nothing but praise for NISSEN energy.After handover, a NISSEN energy service agreement has been entered into. Laholmsbuktens VA is very satisfied with NISSEN energy’s commitment and looks forward to the continued work.

One step closer to self-sufficiency

With the new engine, Laholmbuktens VA has future-proofed the utilization of the biogas produced at the treatment plant.

The lifetime of the plant is calculated to be 15 years with a calculated payback period of ˂ 7 years based on an electricity price of 0.5 Skr. kWh electricity, 0.15 Skr/kWh for heat production, and a return on capital of 1.5%.

By utilizing the biogas, the treatment plant has achieved a degree of self-sufficiency of over 70% of its own consumption of electricity and can produce heat for the digester and for the administration buildings.

In its first ¾ year, the plant has had an uptime of ˃ 94% and with the gas produced, the plant has been able to run with an average load of 82% and produced 2,617 MWel.